Falkbuilt Converts Healthcare Construction from a Disposable Expenditure into a Digital Asset

2025 HCD Conference + Expo in Kansas City

Each October, Falkers across North America look forward to the Healthcare Design (HCD) Conference + Expo. It’s a highlight of the year, a chance for our teams to connect, collaborate, and showcase how Digital Component Construction is addressing some of the most persistent challenges in healthcare construction.

Falkers love to talk about what they do because they’ve seen the difference it makes. Digital Component Construction consistently delivers faster, cleaner, and more predictable results while solving issues that conventional construction faces every day such as skilled labor shortages, schedule delays, and costly rework.

This year marked Falkbuilt’s sixth appearance at HCD, held in Kansas City, Missouri. Once again, our team came together to raise the bar, demonstrating how collaboration, technology, and craftsmanship combine to create high-performing healthcare environments.

Building Digital Assets, Not Disposable Expenditures

Thanks to our technology, Echo, which integrates with industry standard tools like Revit, every element of an interior – from walls, to doors, to millwork, is precisely designed in the cloud, before it’s manufactured. This creates a permanent, stored digital record of the space. When changes are needed, that digital model makes it fast, predictable, and cost-effective to adjust without starting from scratch.

“With Falkbuilt, you’re not just building an interior, you’re creating an asset that grows with your business and adapts to change. That’s the power of turning a disposable expenditure into a high-performing digital asset,” said Mogens Smed, Founder and CEO.

A Total Solution for Healthcare Construction

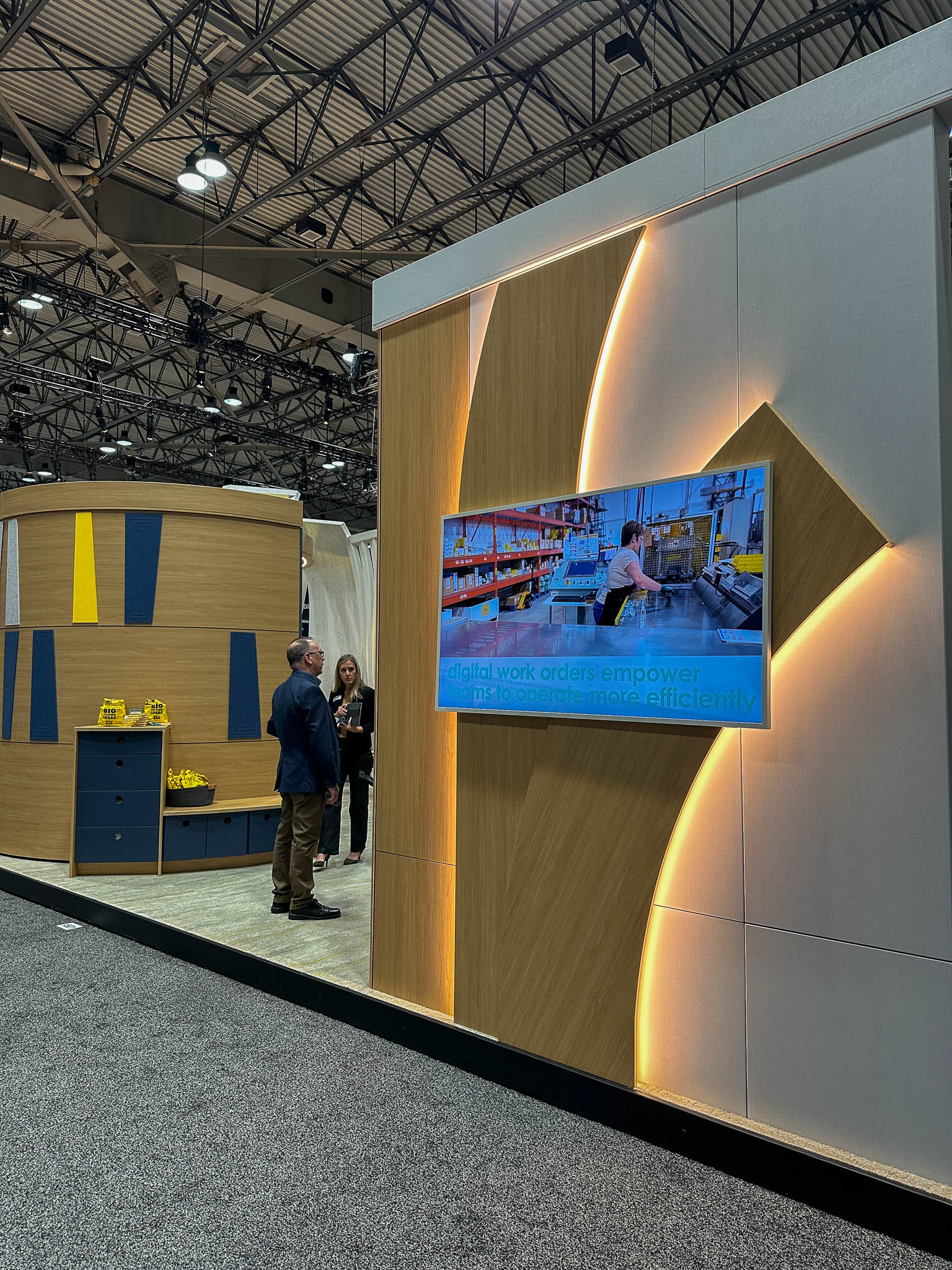

Inspired by Frank Gehry’s Walt Disney Concert Hall, our 2025 booth blends sculptural design with technical precision. Every curved wall, digital component, and material finish reflects the attention to detail and teamwork Falkers bring to every project.

The healthcare booth, dedicated to those impacted by the 2025 Southern California wildfires, showcases the adaptability, performance, and durability that define our healthcare solutions:

- The open wall reveals full accessibility and easy maintenance for electrical and plumbing.

- Curved walls and timber detail and highlight architectural versatility.

- Behavioral health doors are designed for safety and durability - a double swing hinge allows the door to swing in the non-traditional direction in an emergency.

- Stainless steel cladding for surgical operatories ensures infection control and long-term strength.

- Acoustic baffles support privacy and calm in patient areas.

- Bathroom walls demonstrate robust load-bearing capability, holding up to 300 lbs without additional backing.

Fast, Precise, and Seamless Installation

The entire booth was built in just ten hours from crate to completion. That kind of precision and speed comes from teamwork and preparation. What would take weeks with conventional methods was completed in less than a day.

Much of that innovation happens inside the factory. It’s where our teams refine details, test materials, and develop smarter solutions alongside subject matter experts in healthcare, acoustics, behavioral safety, and infection control. By bringing expertise into the manufacturing process, Falkbuilt continuously improves both performance and precision before anything ever reaches the job site.

Immersive Collaboration with Echo

Attendees also stepped inside our Project Immersion Lab (PIL) Box powered by Echo. This immersive experience allowed users to explore layouts, materials, and design changes in real time, all connected directly to manufacturing. It’s a clear example of how Digital Component Construction and Echo are transforming collaboration in healthcare design.

Evolving Healthcare Design with Digital Components

Falkbuilt’s 2025 healthcare booth reflects how far our team, and the industry have come. Every year, our approach evolves through shared experience, collaboration, and continuous improvement. After the show, the booth was disassembled and packed up, ready to be brought back to Falkbuilt HQ for future tours. Its flexibility and reusability demonstrate that sustainability isn’t an afterthought, it’s built into every component we manufacture.

At Falkbuilt, teamwork drives innovation. From concept to factory floor to final installation, Falkers work side by side with industry experts to refine and deliver solutions that perform better, install faster, and last longer. Digital Component Construction is a smarter, faster, and more sustainable way to build.

Join us next year at HCD in New Orleans Oct. 17-20, 2026!

Contact Us!