The "next normal" for interior construction

Fewer trades onsite + surfaces that are cleanable

Everyone wants to get their business moving again. Building owners, tenants and their clients want the doors to open. Architects, designers, engineers, construction companies and trades all want to get back on the job building out space. But there’s no going back to how things were when the global pandemic hit and shut down the construction industry as well as countless others.

As we carefully resume construction activity, we have to minimize the risk of COVID-19 spreading, and that means more than wearing masks and slathering on hand sanitizer. To keep workers healthy and safe on the construction site means there needs to be fewer of them.

In conventional construction, building offices and meeting rooms with drywall and glass fronts requires a number of different types of trades from different companies including drywallers, tapers, painters, glazers and carpenters. Each of these companies may send several people to the construction site, which can add up to dozens in a hurry.

As the trades come and go over many weeks, the site supervisor has to keep track of them all. The more people onsite the bigger the risk and the harder it is to maintain physical/social distancing guidelines. With COVID-19 lurking, the supervisor has to carefully schedule everything to limit the number of people onsite at any given time. Everyone must be checked upon arrival to ensure they are symptom free and that they have the correct personal protection equipment. And forget piling on the elevator together. More trips up. More waiting. More time lost.

It’s the new normal.

Or as RBC CEO David McKay calls it:

“the next normal.”

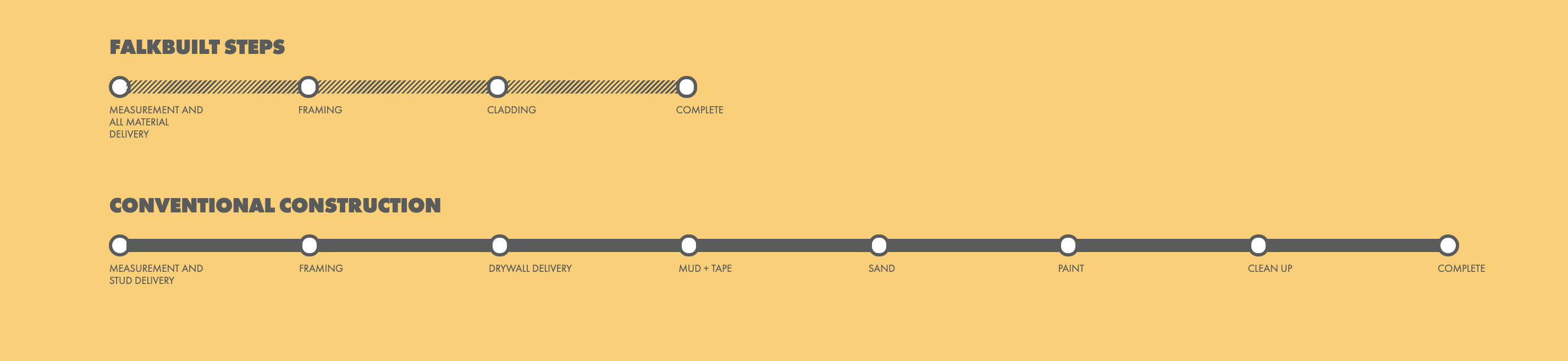

Falkbuilt’s Digital Component Construction is already there. Our process requires only a few trades onsite for much less time to build solid and glass walls and install doors. All the components-super studs, digital horizontals, cladding and millwork-are precision manufactured in Falkbuilt’s factory and are installed quickly and easily by either drywallers or carpenters. Electrical is easier because pre-engineered solutions are mounted on digital horizontals, acoustics are covered and there’s virtually no waste onsite.

With far fewer trades on the job site, just a handful instead of 20 or more, everyone can keep their distance and stay safe. There are fewer elevator trips up. Less hassle for the site supervisor. Plus, with the ever-growing shortage of trades in the construction industry, there is lots of work for everyone. As we all adjust to life in a global pandemic, cost is even more important than ever and Falkbuilt is incredibly competitive. After move-in, Digital Component Construction offers yet another important advantage - unlike porous drywall, durable Falkskin finish is easily cleanable with industrial grade disinfectants.

As we move into the next normal of interior construction, we must think differently, design and build differently. Fortunately, Falkbuilt is already doing just that.

Let's talk new normal

contact